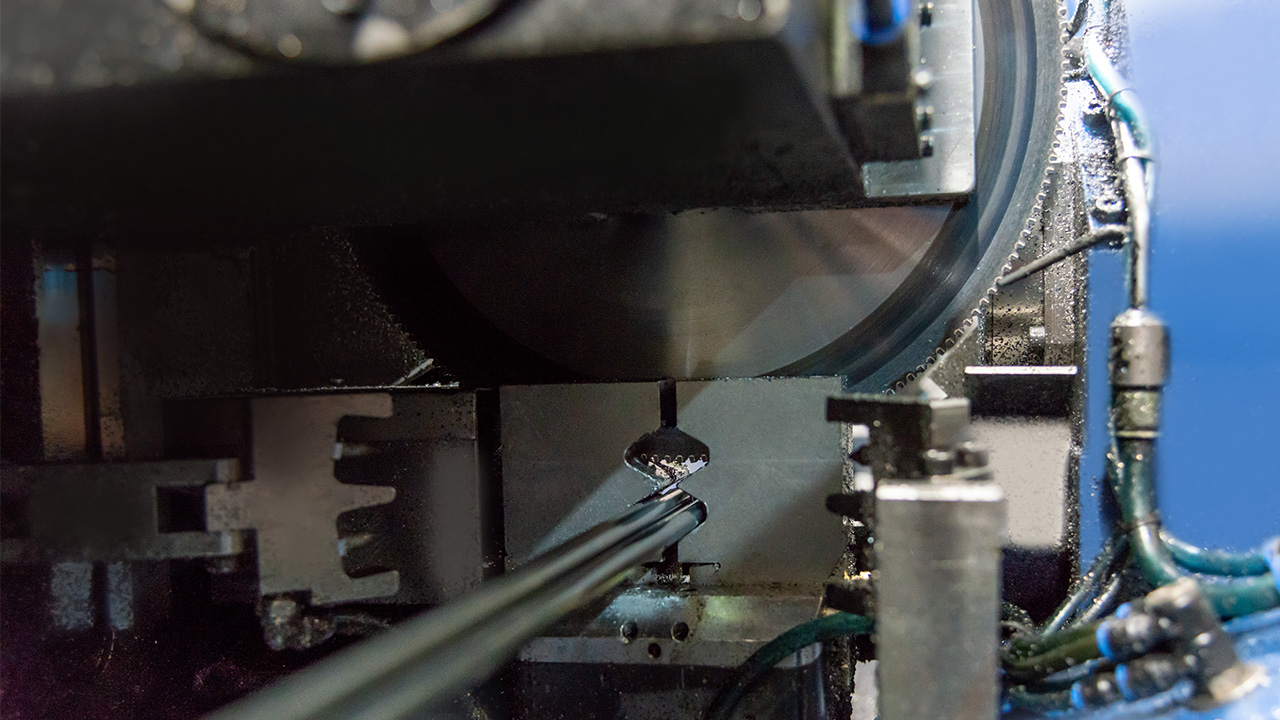

Saw blade cutting

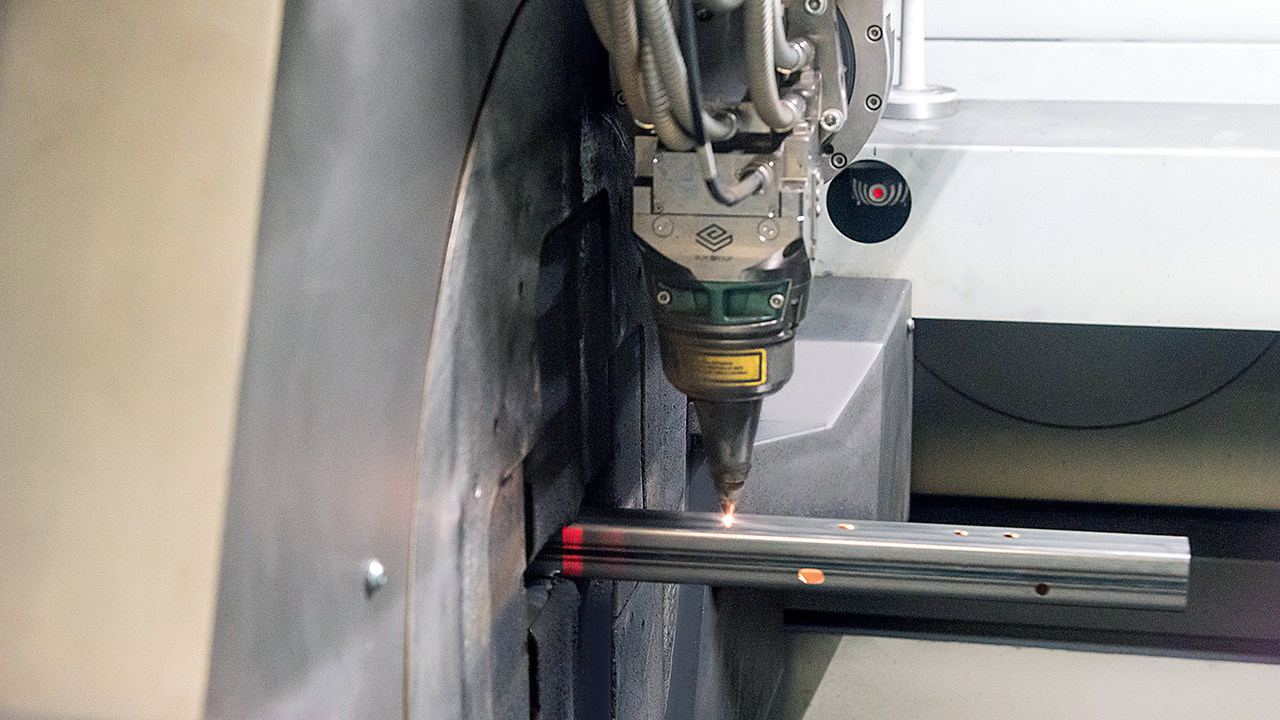

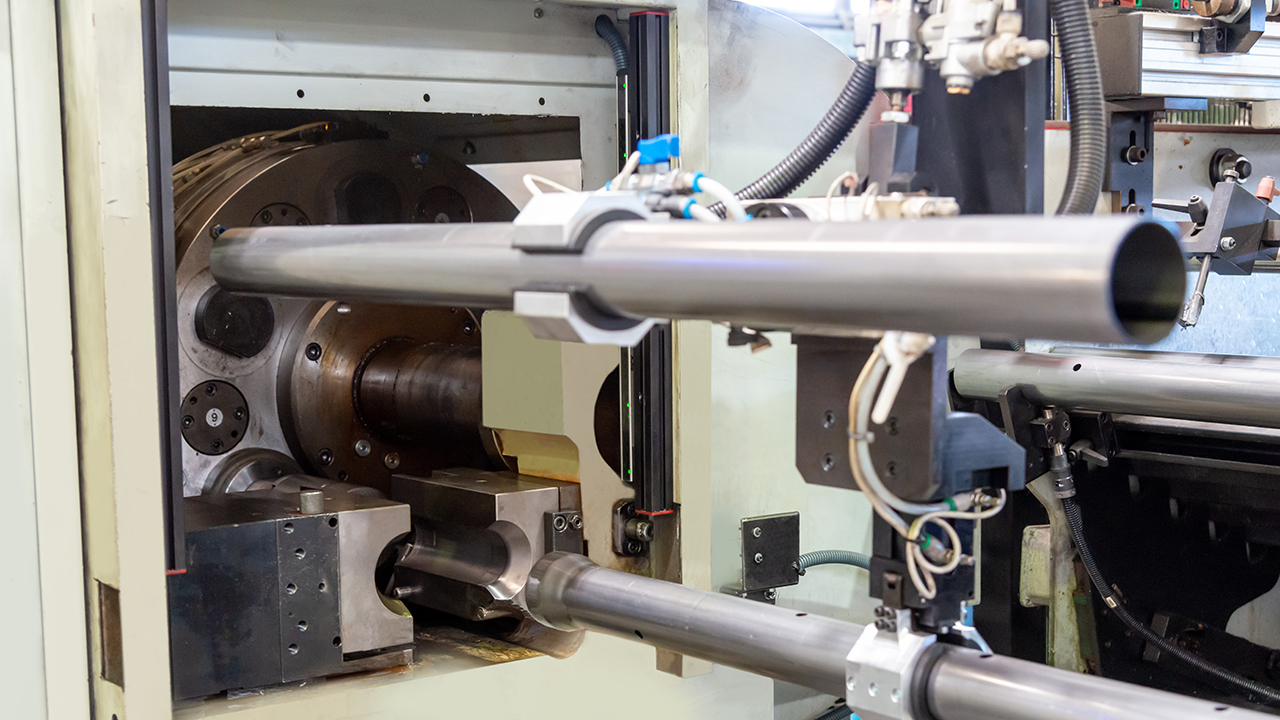

We carry out saw blade cut-to-length operations, offering an integrated service to our clients.

Our state-of-the-art cutting processes cover different degrees of tolerances, lengths, thicknesses and diameters, to provide our clients with global solutions adapted to their needs.